Who can find the one defect ?

Our Systems can !

Products

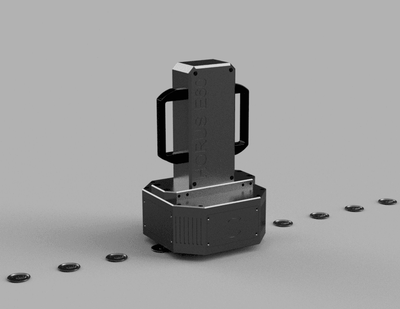

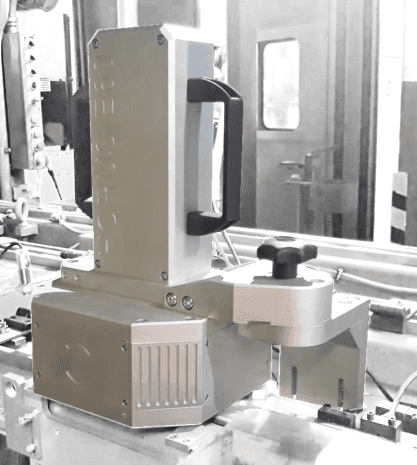

Horus

E - System for Converted Ends & Shells

- Very compact and ruggedized system design

- Easy to move and mount

- CPU & IO at sensor, decentralized -> less cabling required

- High resolution color camera (2 MP, option 5 MP)

- Special LED illumination, configured for best image quality

- High-speed inspection, suitable for all production speeds

- Special defect classification, to sort-out only real defects and thus minimizing spoilage

- Intuitive and modern touch screen user interface

- easy to operate, even by untrained staff

- Well illuminated images with storage and production quality map

- Quality statistics and Excel-export of all data

- Automatic product selection, based on product color or other features

- Optional motorized camera zoom

- Optional multi image shots, for enhanced inspection under different illuminations

- Data exchange with factory MES system

- Easy line integration

- Optional clamping brackets available for all typical conveyors

- no drilling required & easy to mount

- Camera can be rotated away from conveyor

- Easy maintenance / cleaning of conveyor

- Part sensor / speed encoder / part rejector included

- Opto-coupled I/O channels for further line integration

- Ethernet-connection + OPC-UA interface for complete Industry 4.0 integration

- Remote assistance